HVPF vertical automatic press filter can be applied in mining, metallurgy, chemical industry, pharmacy and food industries. It is a kind of high capacity, energy-saving, automatic solid-liquid separation machine.

Supply Range and Requirements on Local Installation

(1) The HVPF vertical automatic press filter is an advanced filtration system that outperforms all others worldwide. Unlike vacuum filters, it utilizes air or water to create a strong pressure difference on both sides of the filter cloth, resulting in highly effective separation of solids and liquids.

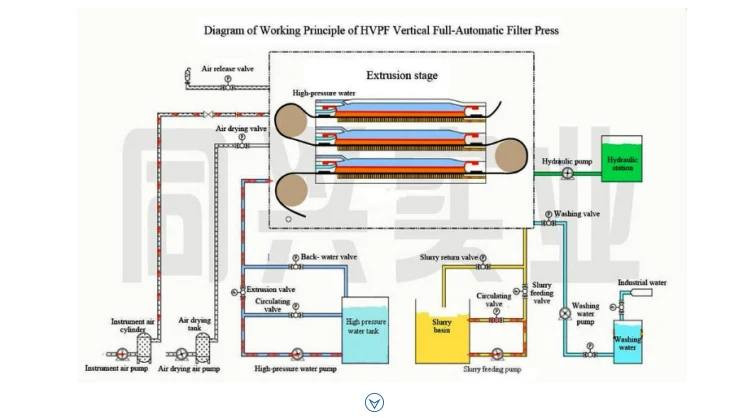

(2) To operate the filter, simply close the filter plate and pump the slurry into the filter chamber using the slurry pipes. Gravity allows a portion of the filtrate to pass through the filter cloth into the filtrate chamber. The high-pressure water then forces the rubber diaphragm to squeeze out the filtrate from the filter cake. Once the process is finished, the filter cloth and filter cakes are discharged from both sides of the filter cloth.

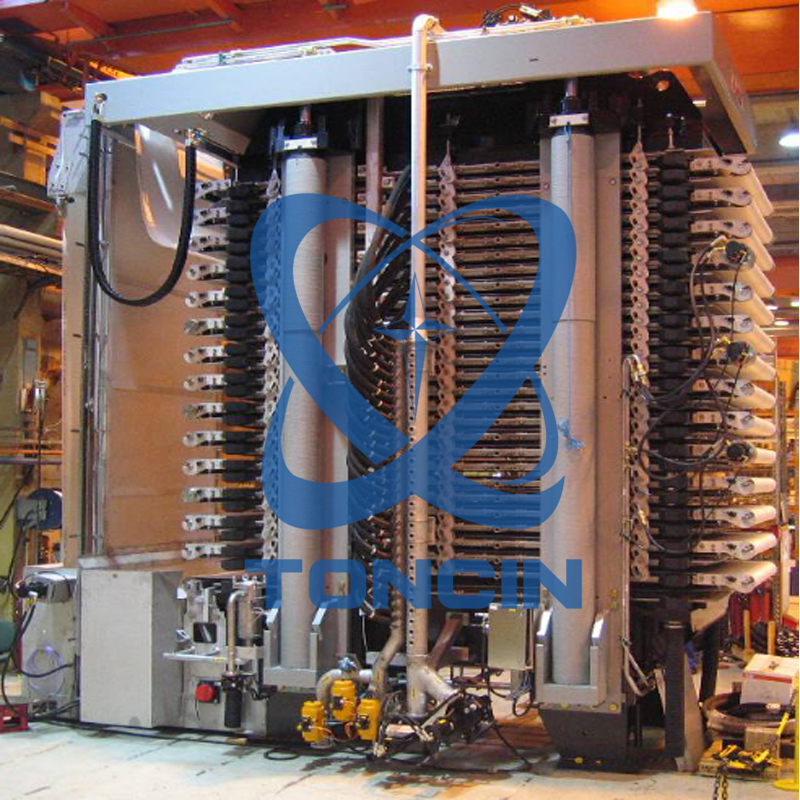

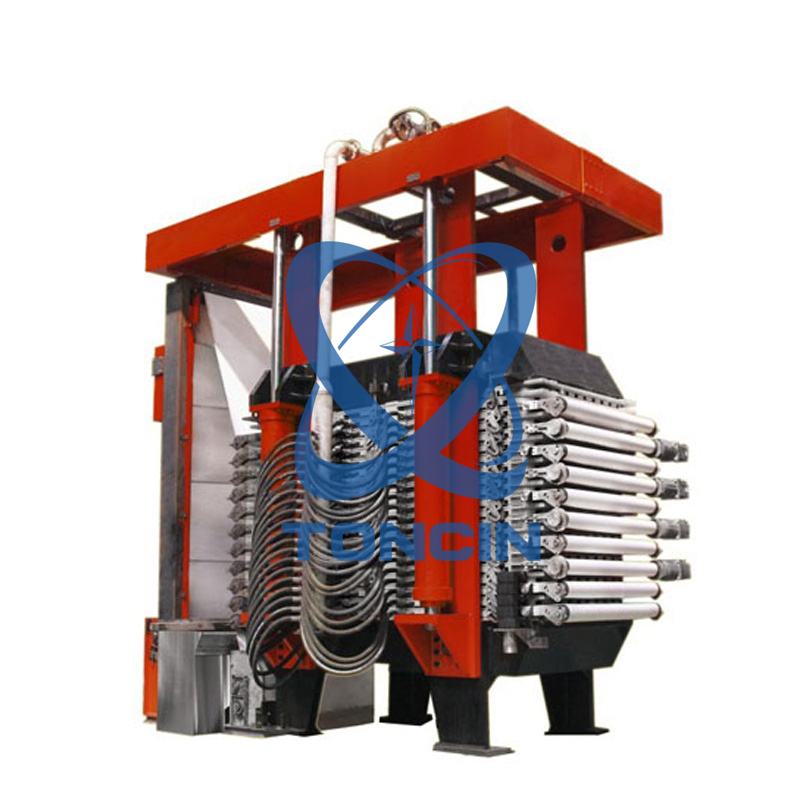

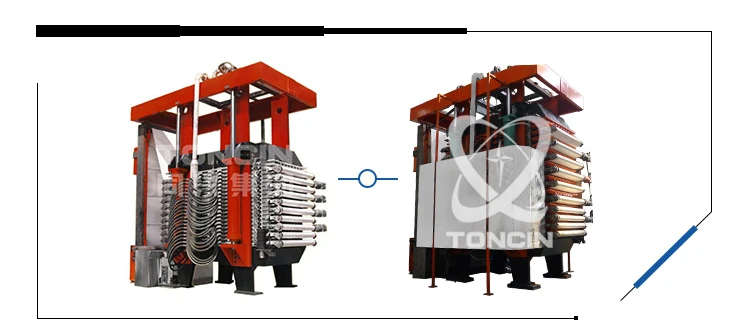

(3) The HVPF vertical automatic press filter consists of various parts, such as the main unit, hydraulic station, water station, cleaning system, and control system.

(4) Before installing the machine, it is important to place it on a sturdy and level surface, such as a reinforced concrete or steel platform. The size of the foundation and other dimensions should be discussed beforehand, and the depth of the groundwork should be determined by the customer based on specific conditions. To prevent any damage, the main unit should be suspended by trained professionals, and a leveling tool should be used to adjust its position and ensure stability.

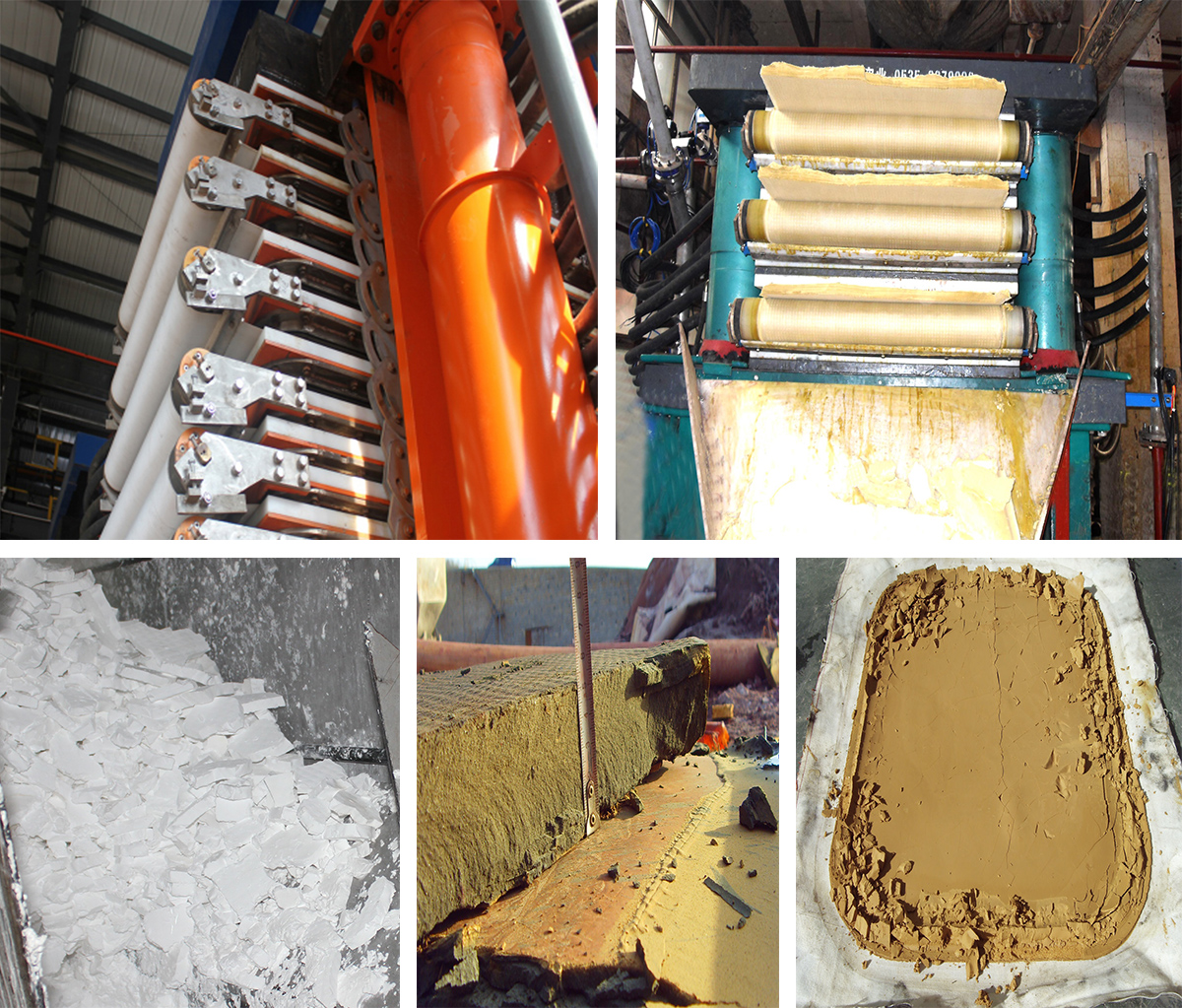

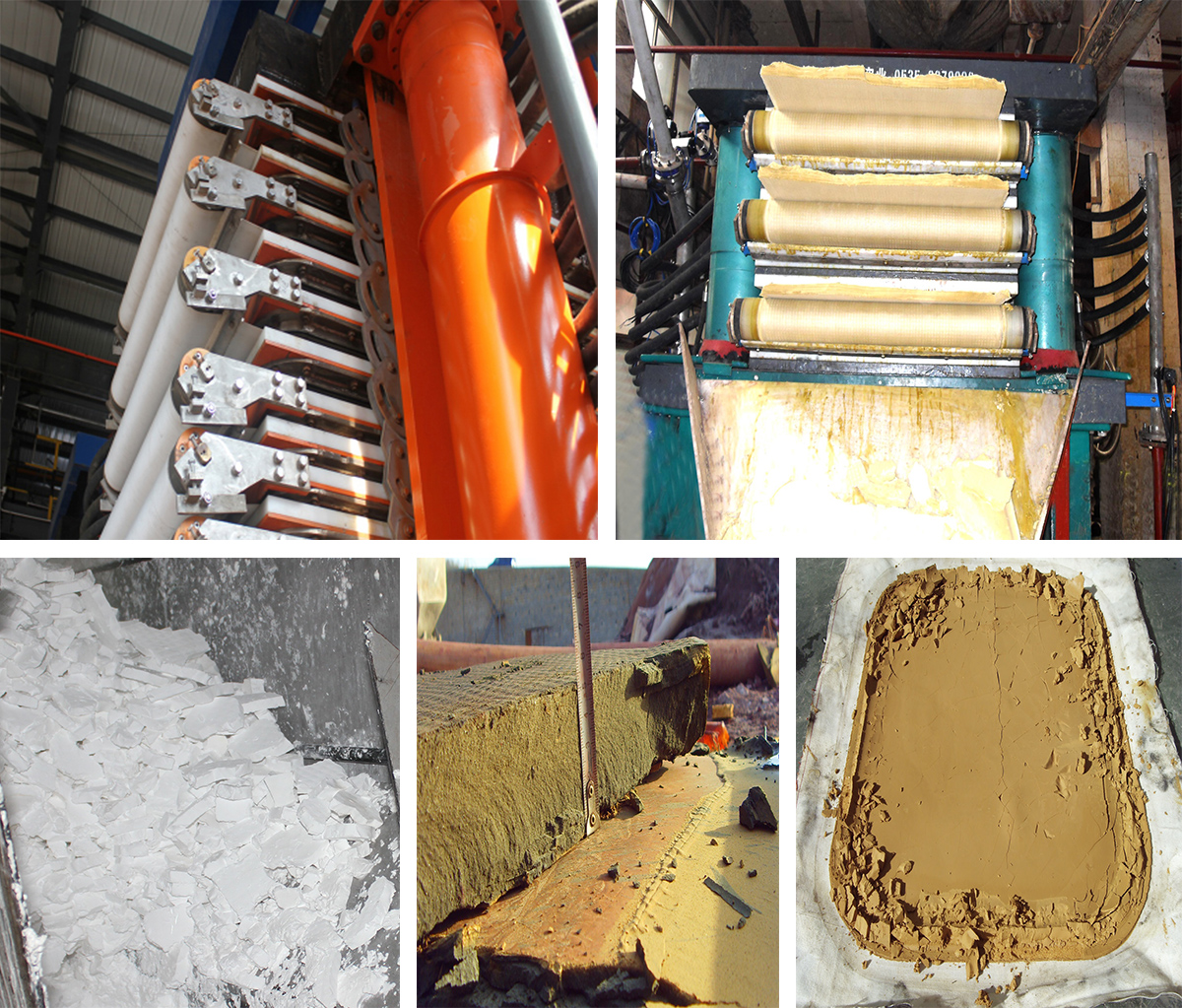

(1) Filtration Stage: Upon sealing the filter plate, the slurry is pumped into the filter chamber via a slurry pipe. The liquid component permeates the filter cloth, entering the filtrate chamber through a filtrate tube, while the solid portion consolidates into a filter cake within the filter chamber.

(2) Compression: Utilizing high-pressure water directed through a tube into a membrane, the membrane applies pressure against the filter cake, expelling filtrate from it.

(3) Cake Rinsing: Washing water is pumped into the filter chamber through the slurry pipe. After rinsing the filter cake, it traverses the cloth and is directed into the discharge pipes.

(4) Air Drying: An airflow containing water passes through the filter cake, effectively minimizing its moisture content. Simultaneously, the filtrate chamber is emptied to enhance the drying process.

(5) Filter Cake Removal: Upon completion of the drying process, the driving components initiate the movement of the filter cloth, leading to the discharge of the filter cake from both sides of the cloth.

English

English